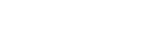

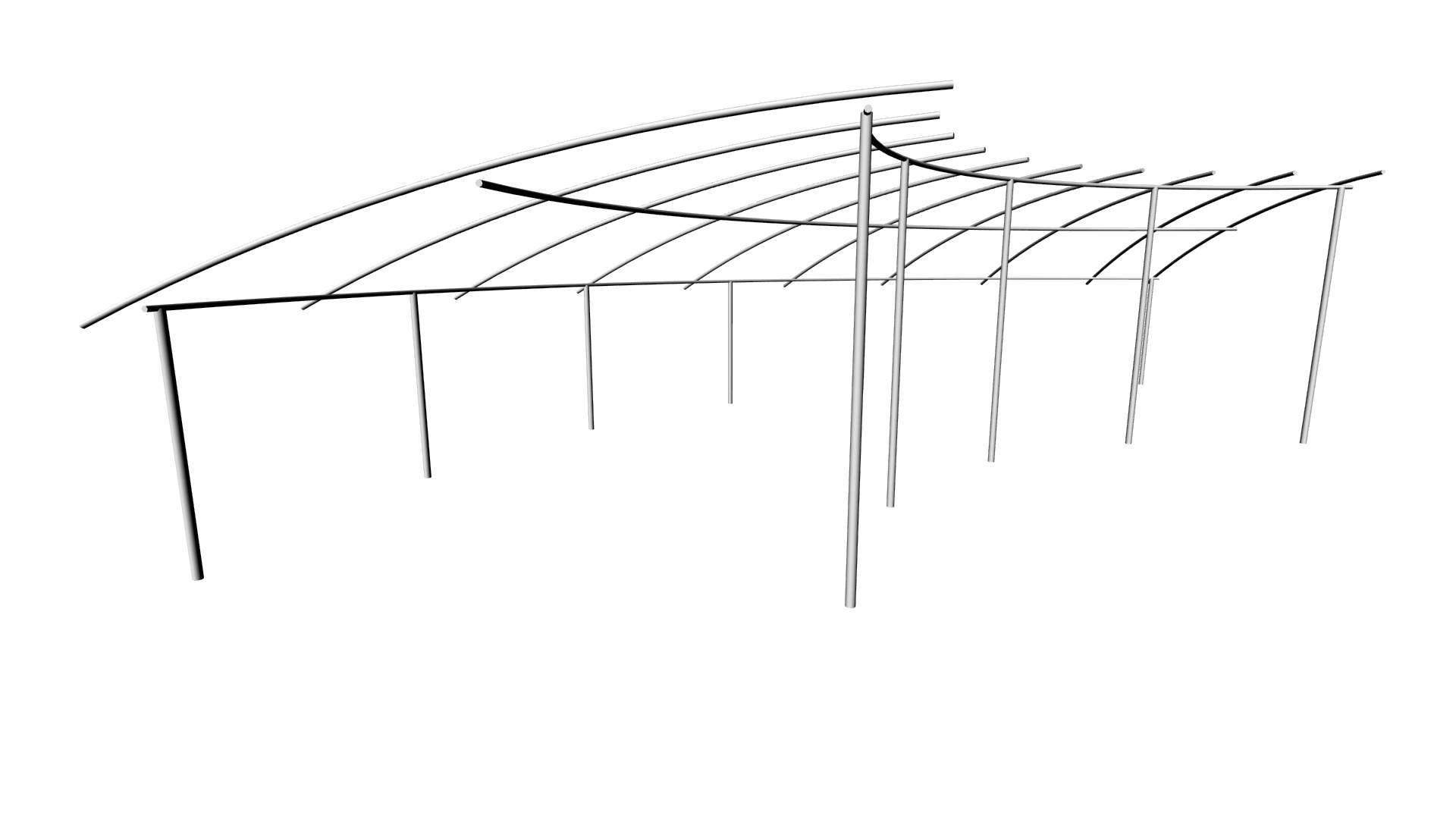

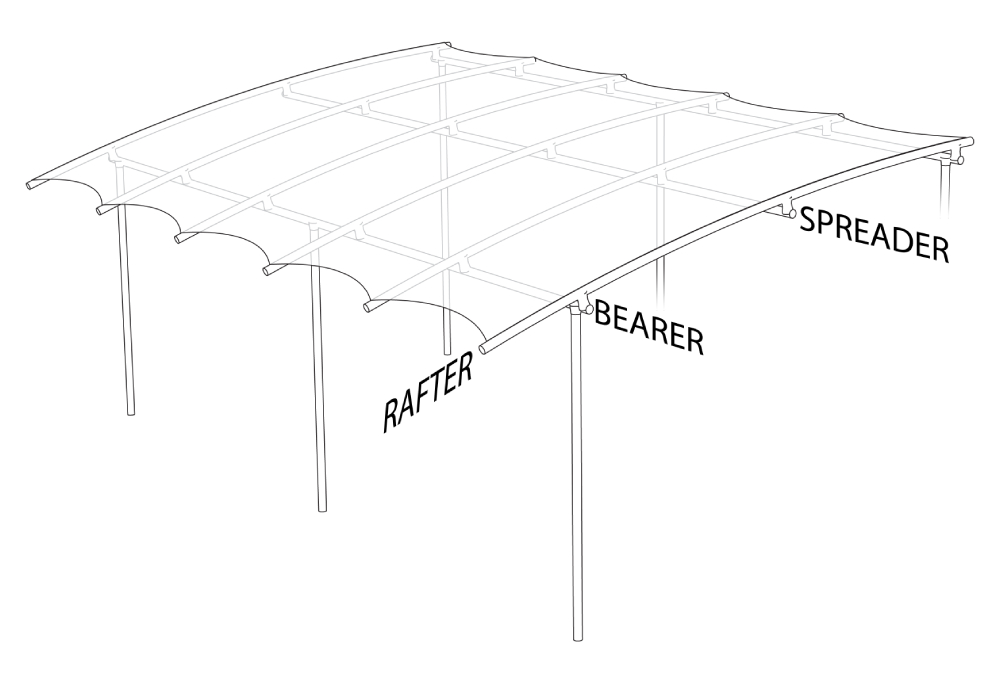

Anatomy of a Triax Structure

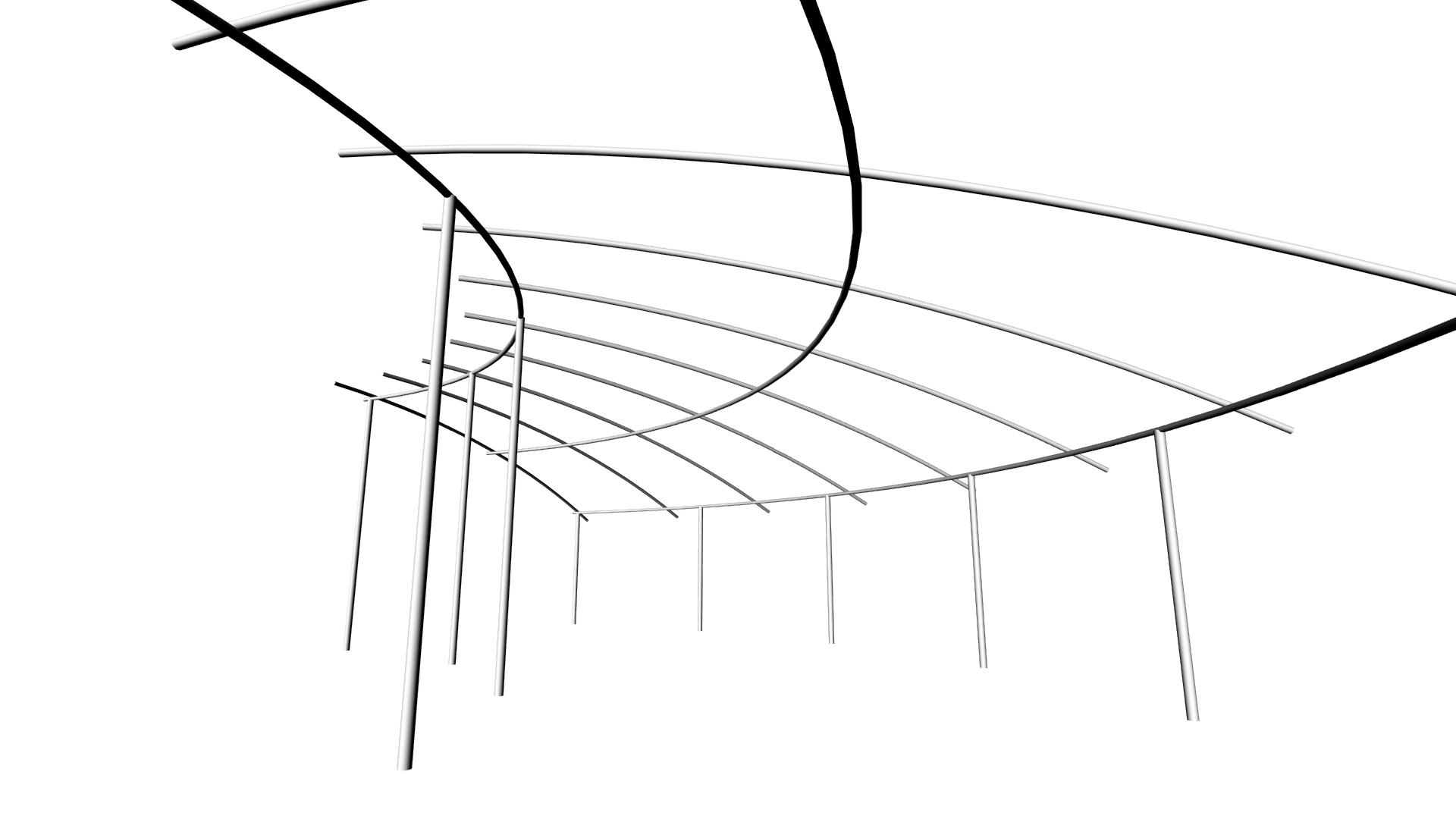

The bearers on either side support the rafters. The spreader bar prevents the rafters from rolling in under the tension of the cover. With Triax system’s couplings you can achieve a span of up to 6m between supporting bearers, which do not need to be level or parallel.

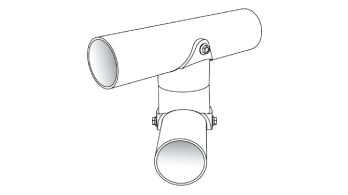

Two Triax T50 brackets bolt together back-to-back to form an adjustable coupling for 50NB pipe.

T50 brackets are also used individually to anchor the bearers in place – bolted to the top of a post, the side of a wall or any other suitably resilient existing structure.

When carrying out a waterproof shade installation, the rafters and Triax couplings are strapped in place before being permanently fixed with Tek screws. This allows the installer to check that the rafter is in the correct position and plumb and adjust if necessary.

FX50 brackets can be used in place of the double T50 couplings if the pipes are crossing at 90° to one another.

EC50 end caps are used to provide an anchor point for the membrane cover at the end of each rafter.

PC80 brackets are used to cap 80NB pipe and provide a clean looking, structurally sound anchor point when attaching a bearer to the top of a post using a T50 bracket.